Tools for HVAC A Complete Technician Guide to Essentials

Last Updated: Aug 11, 2025

The right toolkit turns tough HVAC jobs into routine calls. This guide shows exactly which tools you need and why, so you can diagnose, install, and maintain any system with confidence, speed, and safety.

Essential Hand Tools for HVAC

- Nut drivers and socket set in

1/4 inch,5/16 inch, and3/8 inch sizes with magnetic tips. - Adjustable wrenches sized

6 to10 inch, and ratcheting wrenches for flare nuts in cramped spaces. - Tubing cutter, mini and full size, with deburring tool for clean, leak free copper ends.

- Flaring and swaging kit for joining copper without extra fittings, using clutch style blocks.

- Pipe bender,

3-in-1 or spring style, to prevent kinks in soft copper and line sets. - Insulated screwdrivers, nut setters, and hex keys in long and stubby lengths.

- Pliers set that includes needle nose, channel lock, linesman, and locking pliers.

- Brazing kit with oxy acetylene or air acetylene torch, plus nitrogen for purging lines.

- Hand saw or oscillating tool, utility knife, and fin comb for panels, insulation, and coil fins.

Select chrome vanadium steel for strength, choose cushion grips for comfort, and label sizes with color bands for speed. Always deburr copper after cutting and purge with nitrogen while brazing to keep lines clean.

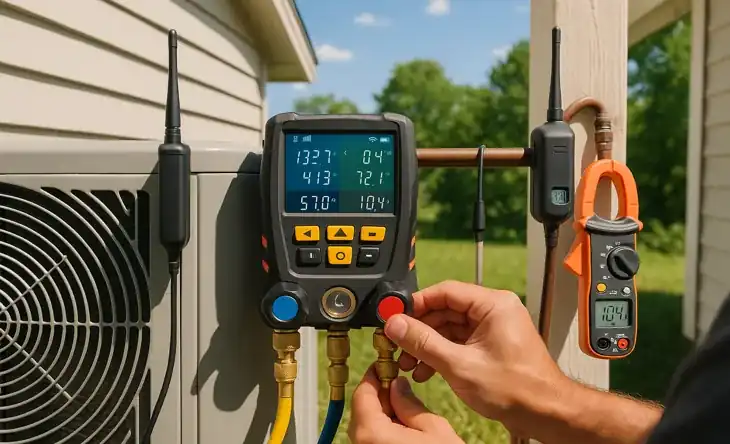

Diagnostic and Measurement Tools

- Manifold gauges, digital or analog, compatible with modern refrigerants such as R-410A, R-32, R-454B.

- Wireless pressure and temperature probes for fast, hose-free readings and automatic calculations.

- Clamp meter and multimeter, category 3 or higher, for volts, amps, resistance, capacitance, and temperature.

- Thermometers and psychrometers to verify supply/return temperatures, delta T, wet bulb, dry bulb, and humidity.

- Infrared thermometer and contact probes for accurate line temperature checks.

- Static pressure kit with manometer and probes for airflow and duct diagnostics.

- Combustion analyzer for fuel fired equipment to ensure safe and efficient operation.

Digital gauges deliver quick superheat and subcool data and save logs, while analog gauges offer reliability without batteries. Confirm delta T between 16 °F and 22 °F with correct airflow and measure voltage drop under load for true electrical health.

Refrigerant Handling Equipment

- Vacuum pump sized by cubic feet per minute, plus core removal tools for faster evacuation.

- Stand alone micron gauge aiming for 500 microns or lower, then perform a decay test.

- Recovery machine rated for A2L refrigerants where required with approved cylinders.

- High resolution refrigerant scale to charge systems by exact weight.

- Low permeation hoses with ball valves and a dedicated large diameter vacuum hose.

- Nitrogen tank with dual stage regulator for pressure testing and line sweeping.

Work sequence pressure test with nitrogen, evacuate to target microns, verify tightness, charge by weight, fine tune with superheat or subcool, and document final readings. Use only A2L compliant tools and follow local codes for new low global warming refrigerants.

Electrical and Controls Tools

- Non contact voltage tester for quick live power checks.

- Clamp meter with inrush current and capacitor test functions.

- Compact multimeter leads, piercing probes, and alligator clips for hands free diagnostics.

- Circuit tracer or toner to follow thermostat and control wiring runs.

- Small screwdrivers, jumper wires, and programming guides for thermostats and control boards.

De energize circuits when possible or wear arc rated protective gear and use category rated meters for live testing. Verify connections contactors and grounds before replacing parts and check control signals against wiring diagrams.

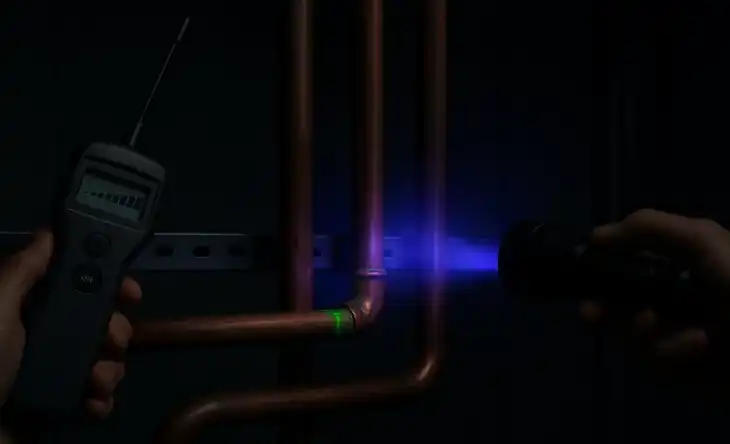

Leak Detection and Sealing Solutions

- Electronic heated diode or infrared detectors suited for

A2L gases. - Ultrasonic detectors that excel in windy or noisy environments.

- Ultraviolet dye kits for slow or elusive leaks confirmed with electronic detection.

- Nitrogen pressure testing equipment with high accuracy gauges.

- Soap solution for pinpoint bubble testing after pressurizing.

After repair perform a decay test to confirm a tight system. Mechanical fixes such as new flares or brazed joints remain the gold standard, while internal sealants are a last resort when approved by both manufacturer and code. Replace Schrader cores and cap gaskets after service to prevent future leaks.

Maintenance and Cleaning Gear

- Aluminum safe coil cleaners with pump sprayer for condenser and evaporator fins.

- Fin combs and soft brushes to realign bent fins without damage.

- Wet dry vacuum and condensate tools to clear traps lines and pans.

- Foam sprayer or gun to improve cleaner dwell time on stubborn coils.

- Surface wipes and corrosion inhibitors for cabinets panels and terminals.

During routine maintenance replace filters, verify delta T and static pressure, clean coils and fan blades, flush condensate lines and tighten electrical connections. Clean equipment runs cooler lasts longer and uses less energy.

Safety Equipment Every Tech Needs

- Safety glasses or goggles and a face shield for cutting and brazing.

- Cut resistant and heat resistant gloves plus chemical rated gloves for cleaners.

- Respirator for coil cleaners and dust masks for dirty attics or crawl spaces.

- Hearing protection for loud mechanical rooms and power tools.

- Lockout tagout kit and electrical rated mats for energized work.

- Gas detector or carbon monoxide monitor for confined spaces.

- Class appropriate fire extinguisher for electrical and combustible hazards

Follow lockout tagout procedures, verify zero energy before servicing equipment, and keep safety data sheets on the truck. Ventilate work areas when handling

Advanced Smart Tools and Software

- Wireless pressure and temperature probes with mobile app integration.

- Data loggers and WiFi gateways for remote performance tracking.

- Bluetooth manometer and airflow hood for quick balancing.

- Cloud based reporting apps to share branded reports and photos with clients.

Smart tools reduce diagnostic time, create documented proof of work, and support predictive maintenance programs. Choose one ecosystem for seamless probe and app compatibility, and keep sensors on a yearly calibration plan.

Organizing and Transporting Your HVAC Toolkit

- Backpacks for rooftop units and ladder work keep your hands free.

- Open top totes for quick access to frequently used tools.

- Rolling cases for heavy meters analyzers and recovery gear.

- Kitting strategy with small pouches for electrical refrigerant brazing and cleaning supplies.

- Foam inserts and shadow boards in the truck to spot missing tools instantly.

- Digital inventory app to track calibration dates and restock items like fuses caps and Schrader cores.

Tool organization saves minutes on each task, which adds up across the busy season, and helps prevent lost tools.

Conclusion

A complete HVAC toolkit blends robust hand tools, accurate diagnostic gear, modern refrigerant equipment, safety essentials, and smart technology. Keep everything organized, calibrated, and ready, and you will finish jobs faster, reduce callbacks, and boost customer satisfaction.